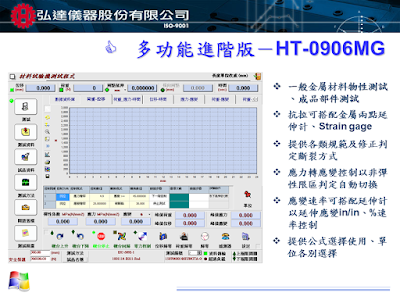

ISO 6892-1:2016 says, strain rate for determination of upper yield strength, ReH , or proof strength properties, Rp and Rt; during determination of these material properties strain rate, eLe, shall be in one of two following pecified ranges.

Range 1: eLe = 0.00007 s-1

, with a relative tolerance of ±20 %.

Range 2: eLe = 0.00025 s-1

, with a relative tolerance of ±20 % (recommended, unless otherwise specified).

Strain rate for determination of the lower yield strength, RLe, and percentage yield point extension, Ae,

following the detection of upper yield strength, estimated strain rate over parallel length, eLc, shall be

maintained in one of following two specified ranges until discontinuous yielding has ended.

Range 2: eLc = 0.00025 s-1

, with a relative tolerance of ±20 % .

Range 3: eLc = 0.002 s-1

, with a relative tolerance of ±20 %.

Strain rate for the determination of the tensile strength, Rm, percentage elongation after fracture, A,

percentage total extension at the maximum force, Am, percentage plastic extension at maximum force, Ag, and percentage reduction area, Z After determination of the required yield/proof strength properties, the estimated strain rate over the parallel length, eLc shall be changed to one of the following specified ranges.

Range 2: eLc = 0.00025 s-1

, with a relative tolerance of ±20 %.

Range 3: eLc = 0.002 s-1

,with a relative tolerance of ±20 %.

Range 4: eLc = 0.0067 s-1

, with a relative tolerance of ±20 % (0.4 min-1 with a relative tolerance of ±20 %).

If the purpose of the tensile test is only to determine the tensile strength, then an estimated strain rate over parallel length of the test piece ccording to range 3 or 4 may be applied throughout the entire test.

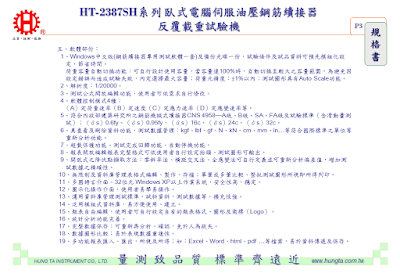

ASTM E8:2016 standard specifies that “Control Method C - Crosshead Speed Control Method for Determining Yield Properties”- The testing machine shall be set to a crosshead speed equal to (0.0156 ± 0.003) mm/mm/min of the original reduced parallel section. However, ISO 6892-1:2016 Method A2, open Differences of Latest Versions of ISO 6892-1 and ASTM E8 Tensile Testing Standards 17 loop strain control, involves the control of the estimated strain rate over the parallel length, (eLc), which is achieved by using the crosshead separation speed (Vc) calculated by multiplying the required strain rate by the parallel length.